Stabilization Bake

Stabilization Bake / High-Temperature Storage

Stabilization bake is a process step defined by MIL-STD-883 and is primarily intended to reveal any performance impact high storage temperature over long term may have on a device prior to applying electrical stress. “High-temperature storage” is another definition of this process more commonly used by non-military applications and with JEDEC related process flows.

This process can be either implemented as:

A – A production process applying heat treatment to “stabilize” or reduce mechanical variability and as a function reduce electrical variation within a given batch. Similar to an annealing step.

B – A control process to identify thermally activated failures and respective failure modes within a given batch

C – Part of a sample screening test flow including a post-bake electrical test to ensure the sample can move onto the main qualification flow and to identify any variability outside of expectation.

Whether A, B or C, the result is that the stabilization bake test helps to identify and removes any risk of introducing flawed product further down a process flow where these failures are exclusively attributed to high-temperature storage conditions.

The test is conducted by serializing devices and taking end point measurements and where necessary intermediate measurements to generate data across a sample. The sample size and data collection protocol can be tailored to the sensitivity of the device or to target a known likely failure mode or parametric drift over time.

At Reltronix we perform all testing in our Class 10K compliant laboratory and use stabilization chambers which are highly accurate and maintain their storage temperature within +/- 0.5°C.

Stabilisation Bake Oven

Timing and sequence of the test is important, all test candidates must dwell in ambient temperature before bake and the total time under high temperature must also account for rise timing for all devices to reach target temperature. Ambient temperature exposure is influenced by chamber profile, load distribution of the sample and airflow. The chamber control system sensor uses a high resolution temperature sensor which is intermittently calibrated via external monitoring. After the stabilization bake end-point measurements should be completed within 96 hours. Component testing is typically performed using our wide suite of electrical test equipment.

Stabilization Bake Standards

We perform stabilization bakes to the following industry standards:

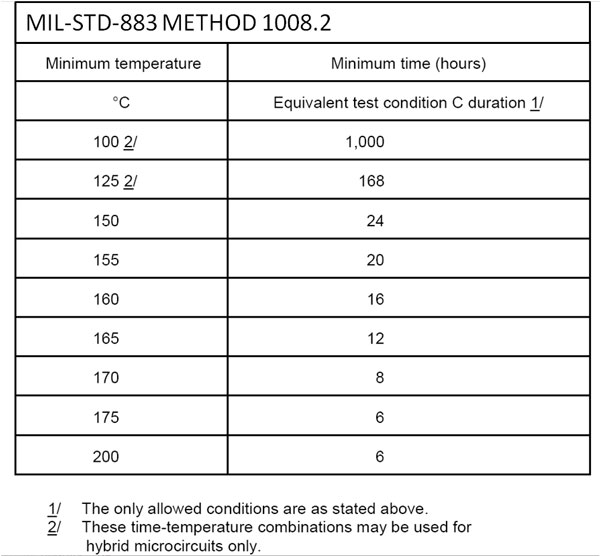

MIL-STD-883 Method 1008.2

JESD22-A103E.01

Stabilization bake / high-temperature storage is not considered a replacement for burn-in or life testing because there is no electrical stress applied to the test samples. However is effective for identifying failure modes accelerated by purely temperature only such as oxidation, wire-bond integrity and intermetallic growth.

We also apply stabilization bake to enable the following MIL-STD processes:

MIL-PRF-38534 Para C.6.3.2.4 (in association with Method 2011 of MIL-STD-883 for Class H and Class K qualifications) – Assessment of wire-bond integrity after 300 degrees C high-temperature bake

MIL-PRF-883 Test Method 1014 – Stabilization bake prior to lid seal in order to remove impurities and out-gassing potential.

Sales & Support

Mechanical Testing

We offer a comprehensive selection of mechanical tests, from ball shear, die shear, wire bond pull to SEM inspection.

Electrical Test

Semiconductor testing to Mil-PRF-38534 Class H & Class K.