Mil-PRF-38534 Class H

The MIL-PRF-38534 Class H electrical test standard describes the evaluation criteria for semiconductor bare die used to assemble military-grade hybrid and MCM (Multi-Chip-Module) circuits. The standard originates in the USA and is globally recognized; as such the standard is often considered a baseline for customers to specify their component qualification needs. For this reason the standard may also be relevant when considering medical & high-temperature industrial applications. There are multiple pseudonyms used in the industry for this test process including “Class H Element Evaluation (EE)”, “Class H Lot Qualification” or “Class H Lot Acceptance Test (LAT)”.

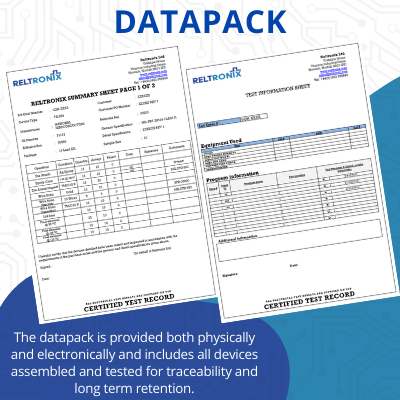

At Reltronix the test flow is applied in exact accordance with MIL-PRF-38534 Class H. The product is a comprehensive datapack containing:

• Process Flow Traveller

• Mechanical Test Results

• Electrical Test Results at room temperature plus hot and cold datasheet limits

• Certificate of Conformance.

The datapack is provided both physically and electronically to the customer and includes all devices assembled and tested for traceability and long term retention.

Our certificate of conformance certifies we have tested the candidate devices against this standard irrespective of pass or fail. Where they meet the standard, a certified level of quality assurance for the device is provided. Where they do not meet the standard, the test data pack is still provided with detailed electrical information available for customer consideration and analysis.

The coverage of the Class H electrical test flow is wide and via assumption of production homogeneity, permits that data obtained from one wafer is also representative of the other wafers produced within the same specific manufacturing lot. For that reason Class H qualification provides a level of quality assurance across a larger quantity of production material.

For applications where higher quality assurance is needed such as Space or where reliability over operating lifetime must be evaluated, consider MIL-STD-385354 Class K.

MIL-PRF-38534 Class H process flow:

Sample Selection

Single diffusion – can span multiple wafers if required

Sample size – 20 PCS (5 destruct)

Pre-Sample Assembly

Die Visual Inspection – MIL-STD-750/TM2072/TM2073/TM2074, MIL-STD-883/TM2010B

Sample Assembly

Die Attach – MIL-STD-883/TM2010

Die Shear Test – MIL-STD-883/TM2019

Die Attach Inspection – MIL-STD-883/TM2011

Wire bond – Internal spec

Pre-Cap inspection – MIL-STD-883/TM2010

Internal Die Visual – MIL-STD-883/TM2010B, MIL-STD-750/TM2072, MIL-STD-75/TM2073

Package seal – MIL-STD-883/TM1014

Seal Inspection – MIL-STD-883/TM2009

Sample coding – Internal spec

Sample Testing

Electrical Test @ 25°C – In accordance with device specification

Electrical Test @ 125°C or THIGH – In accordance with device specification

Electrical Test @ -55°C or – In accordance with device specification

Mechanical Testing

Wire bond integrity – MIL-STD-883/TM2011

Datapack Output

Electronically in archive format such as .zip or similar and also physically (including test samples).

Outgoing Die Release*

*If we are supplying production bare die via our sister company Die Devices the datapack is typically supplied in tandem.

We can perform Class H qualification on a broad range of semiconductor devices, please check out our test capabilities for further information.

If you need silicon processing prior to the Class H qualification step, such as wafer probing, wafer dicing or pick and placing, these options are also available.

Sales & Support

Environmental Testing

We offer a selection of in-house environmental tests, such as centrifuge acceleration, life burn-in, stabilization bake and thermal shock temperature cycling.

Mechanical Testing

We offer a comprehensive selection of mechanical tests, from ball shear, die shear, wire bond pull to SEM inspection.