Centrifuge Acceleration

The Constant Acceleration Test or centrifuge as alternatively known is performed on semiconductor devices to determine adverse mechanical effects. The test practice is designed specifically to uncover structural and mechanical weaknesses in interface between die and package and also the package itself which are not simply detected by alternative mechanical stress tests like shock or vibration.

The centrifuge process can be used as a maximum stress test to determine mechanical strength or limitations of:

a) Die bond to substrate

b) Wire bonding from die to package

c) Internal lead-frame system or pin structure on the package

Constant acceleration or centrifuge can also be applied at lower controlled stress levels as part of a 100% device screening flow which is non-destructive. The purpose of this approach is to weed out and identify components with lower overall mechanical strength and cause them to exhibit failure further down the test flow.

The industry reference standard for performing constant acceleration/centrifuge testing is Mil-Std-883 Method 2001

To summarize the process

High precision high power equipment is used to apply specific acceleration to the samples under test for a fixed time period. Careful attention is paid to the housing of samples such that the sample casing or body is fully exposed to the applied force.

The constant acceleration test employs an apparatus capable of applying the specified acceleration to the devices being tested for the required period of time. In accordance with the Mil-STD the specific level of constant acceleration is applied to the samples for 1 minute for sample orientation: X1, X2, Y2, Y1, Z1, and Z2. There are variations of this process depending on the component specification or customer requirement. For samples where internal elements are mounted having the major seating plane perpendicular to Y axis, the Y1 orientation is specified as most likely to displace the elements from their mount.

Acceleration loads are expressed in terms of load factors that, although dimensionless and typically are labelled as “g” loads.

Table 1 lists the test conditions for constant acceleration testing as defined by Mil-Std-883 Method 2001. Test condition E shall apply, unless otherwise stated.

Table 1. Test Conditions for Constant Acceleration Testing

per Mil-Std-883 Method 2001

| Test Condition | Stress Level (g) |

| A | 5,000 |

| B | 10,000 |

| C | 15,000 |

| D | 20,000 |

| E | 30,000 |

| F | 50,000 |

| G | 75,000 |

| H | 100,000 |

| J | 125,000 |

What we do

At Reltronix we can perform both qualification on a sample basis or on a 100% screened basis.

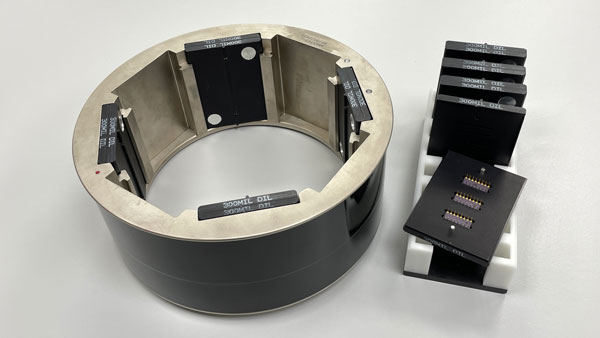

For each casing/package type holders are precision-tooled to retain the sample correctly and ensure load balancing in the chamber. Holders can be tooled on a sample basis or for volume production testing.

To assess your needs for centrifuge service we need the following information:

- Component detail, casing, external, internal

- Test condition to apply either industry standard or custom but in particular the amount of acceleration to be applied in G

- Specification and sequencing of the orientation(s) to be used

Alternatively we can recommend a specification based on your specific application needs where deviation from Mil-STD Method 2001 is appropriate or required.

Sales & Support

Mechanical Testing

We offer a comprehensive selection of mechanical tests, from ball shear, die shear, wire bond pull to SEM inspection.

Electrical Test

Semiconductor testing to Mil-PRF-38534 Class H & Class K.