Die Shear

Die Shear Testing

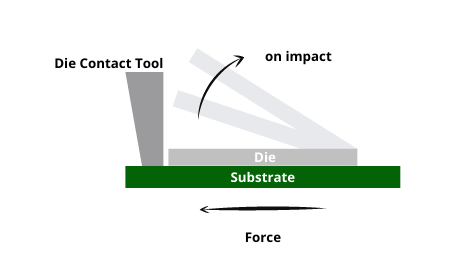

Die shear testing is used to test the integrity of materials and the strength of the adhesion between a semiconductor die and a substrate. Typically, die are attached to the substrate with either epoxy die attach or eutectic die-attach. It’s the quality of this process that is measured during the die shear test. Force is applied against the edge of the semiconductor die with a die contact tool which closely approximates a 90° angle with the base of the header or substrate to which it is bonded. For rectangular die, the force is applied perpendicular to the longer side of the die. The shear strength is measured by the force required to separate the die from its mounting on the package or substrate. We can apply force from a few grams to as much as 1000kgf. Visual inspection is performed to check the appearance of the die and substrate.

Die shear strength testing is often performed alongside other semiconductor mechanical tests, such as Wire-Bond-Pull, Ball-Shear, Life-Burn-In and SEM-Inspection.

Standards

Testing is performed to MIL-STD-883 2019.9 for die shear strength.

Equipment

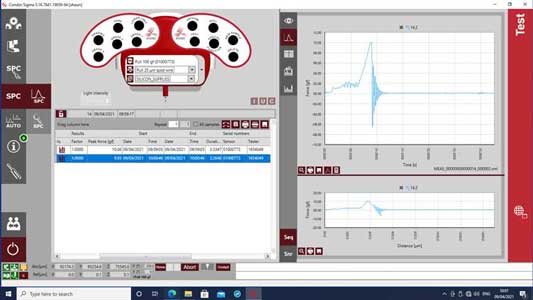

All die shear strength tests are conducted using our in-house XYZTEC Sigma Lite tester. Equipped with automised robotic handling and a high force self-aligning die shear tool. The contact tool has automatic rotation alignment with the die. Images are processed with high-resolution cameras.

Sales & Support

XYZTEC Sigma Lite tester

Die Shear Tests

Please contact us with your mechanical test requirements.